Welding

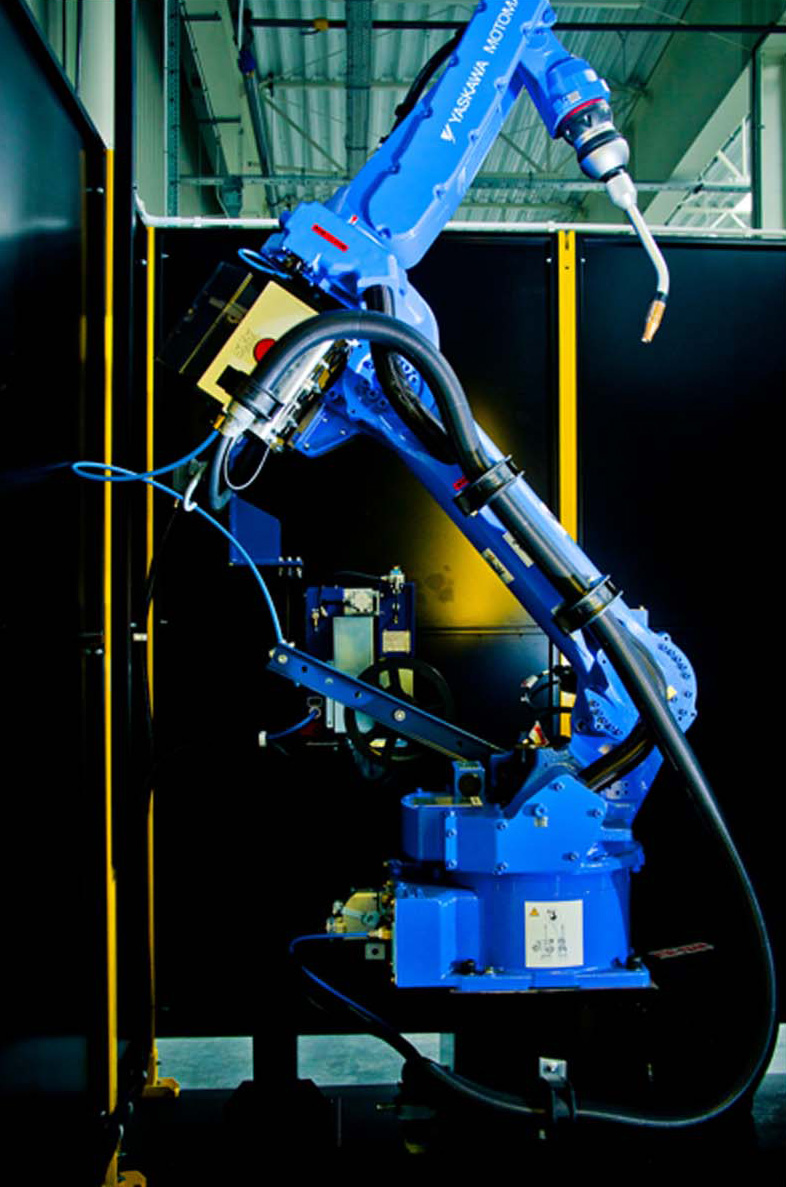

Based on modern SKS solutions, we have prepared a robotic welding cell that guarantees high quality and repeatability of the welding process. The cell is equipped with a reliable 5-axis Yasakawa Motoman robot with a large range of motion. Welding is carried out using the MIG / MAG method. The greatest benefit of using MIG / MAG welding is controlled material passage. In the basic current phase, the energy supply is reduced so much that the welding arc only glows steadily, preheating the part’s surface and maintaining a give temperature. The main current phase with a precise dosing of current, ensures a defined drop detachment. This prevents an undesirable short circuit with simultaneous drop explosion and uncontrolled welding spatter.

Advantages:

– good melting performance,

– deep melting,

– Easy-to-use

– full mechanization,

– high profitability,

– the possibility of observing the weld pool and the arc,

– the possibility of welding a wide range of materials,

– high process efficiency,

– the possibility of mechanization and robotization of the process.

The method is used for joining unalloyed, low-alloy and high-alloy steels, aluminum and its alloys, magnesium and its alloys, nickel and its alloys, copper and its alloys and titanium alloys